Polish Borsuk IFV Unveiled? Two Variants of the New Vehicle

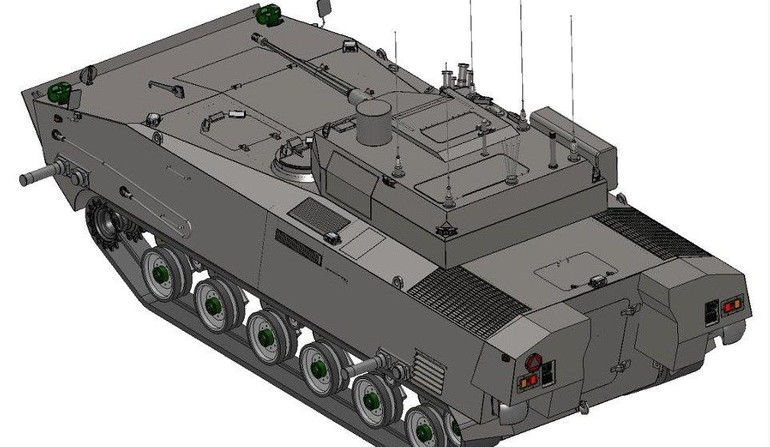

Implementation of the programme, the goal of which is to develop the new Polish Borsuk IFV has been accelerated, which may be witnessed and which is exemplified in the approval of the work carried out so far, along with the feasibility study and the initial tactical and technical assumptions of the programme. Completion of all of the aforesaid steps paved the way towards receiving the relevant funds. Series manufacturing of the new platform is to begin in 2019. Huta Stalowa Wola declares that alongside the basic, amphibious variant, heavier armour version, with a mass of more than 40 tonnes, would also be made available.

Huta Stalowa Wola is currently working on an amphibious IFV, also known under the name of “Borsuk” [Eurasian Badger]. The programme is being pursued within a project managed by the National Centre for Research and Development, on the basis of the relevant agreement which has been concluded on 24th October 2014. According to the information we have been able to obtain, the newly designed platform is to be ready for production in 2019, while the first deliveries are expected to happen in 2021 or 2022.

Throughout the recent period, the required documentation defining the stages of work completed so far, has been transferred to HSW S.A. from the National Centre for Research and Development, along with the feasibility study and the initial technical and tactical assumptions, applicable within the “Borsuk” programme. The rumours related to the planned “redefinition” of the requirements turned out to be untrue, as it became clear that the army is still willing to acquire an amphibious IFV. Financing of the further works has also been unlocked.

Discussion related to the amphibious capability requirement has been going on for ages, when it comes to the modernization process pertaining to the Polish mechanized units. It was a hot topic both during the cancelled BWP-1 “Puma” upgrade project, as well as during the Rosomak APC programme. The arguments mentioned so far are connected to the degree of protection for the vehicles and the modernization potential, and to the increased complexity of design on one hand (which entails increased weight), and making it possible for the IFV to carry out reconnaissance, insertion, anti-access operations, and to freely operate within lake districts, on the other. HSW, since several years, has been working on a design of an amphibious IFV, in line with the requirements of the Ordering Party. Considering the global trends in the IFV design, it is also expected that a heavier variant of the vehicle (40 tonnes) would be developed too.

After the BMP-1 vehicles were introduced into the inventory of the Polish Army (the vehicle, under the TB-40 designation, was to be manufactured at Huta Stalowa Wola, where a modern manufacturing facility has been established, and where almost whole design documentation has been translated into Polish), with 1300 vehicles remaining in service, the platform did not undergo any modernization or upgrades. The transformation of 1989, and the prospect of Poland joining NATO, have both fuelled the debate over the options of modernizing the BMP-1 vehicles which, at the time, were almost 30 years old.

Subsequent, newly developed or hybrid concepts, all of which were one by one rejected by the Polish Ministry of Defence (BWP-2000, BWP-95, BWP-1M “Puma”, BWP-40), were completely new or involved a fusion of the BMP-1 platform with the western turrets (GM Defence Delco, OTO Melara, Bofors, Rafael, GIAT, Elbit, Rheinmetall Landsysteme et al). The designs created at the time, partially enhancing the level of ballistic protection, were placed far away from the amphibious capability requirements, as the initiatives were based on the contemporary BMP-1 modernization initiatives, implemented by the Czech Republic or by Slovakia. BWP-1M “Puma” programme was ultimately closed back in 2009.

During the same year, the outline of requirements defining the shape of a new IFV has been shaped. The emphasis was placed on maintaining the amphibious capability, however high level of ballistic protection was also required, which made the work even more difficult. Most of the western designs have never met, and still do not meet the aforesaid requirement (e.g. ASCOD, Warrior, CV-90). It was decided that a new generation vehicle would be created, within the framework of a development work.

At the same time, the leadership of the Polish Ministry of Defence completely resigned from modernization of the BWP IFV, which, in practical terms, meant that until the moment when newly developed vehicles are received, the units using the post-Soviet platform cannot expect any significant increase of combat value of the IFV. On the other hand, German “Marder” IFVs which have been included in the inventory of the German Army since the 1970s, constituting a response to the Soviet BMP-1 platform, have undergone numerous upgrades, even despite parallel introduction of the “Puma” vehicle, another stage of this process is being considered.

The first attempt to create the new Polish IFV has been made on the basis of an agreement signed on 23rd December, by a consortium formed by OBRUM and Polish Defence Holding [PHO]. The project, divided into 19 tasks, with a budget exceeding PLN 20 million, was to be implemented until November 30th 2014. In July 2012 the financing was suspended on the part of the PHO, and then it was restarted, in January 2013, on condition that the IFV is designed as an amphibious vehicle, and provided that it is based on a chassis derived from a design provided by a foreign partner, even though this condition was very hard to be met to say the least, due to the amphibious capability requirements which could not have been and still cannot be conformed with by most of the designs available on the global market. Back in February 2013, the PHO decided to first provide financing for a combat support vehicle/main battle tank demonstrator.

Obviously, considering the developments above, the works on the IFV were significantly limited, and ultimately, the demonstrator planned to be presented during the 2014 MSPO defence salon has not been unveiled. The works within that scope were formally ended by the decision issued by the Ministry of Treasury, on March 17th 2014.

The issue of developing the NPBWP “Borsuk” vehicle was transferred to a new consortium, established in 2013, led by HSW S.A.. Huta Stalowa Wola has accumulated a lot of experience in designing and manufacturing tracked-armoured vehicles with amphibious capabilities, starting with the license-manufactured 2S1 122 mm “Gvozdika” self-propelled howitzer, finishing with armoured carriers and MT-LB and “Mors”/TRI “Hors”/”Lotos” artillery tractors, along with the “Opal” and SPG-2 chassis family.

The aforesaid consortium also included the following entities: ROSOMAK SA, Wojskowe Zakłady Motoryzacyjne SA [Military Automotive Works], Wojskowe Zakłady Elektroniczne SA [Military Electronic Works], Wojskowe Zakłady Inżynieryjne SA [Military Engineering Works], Wojskowy Instytut Techniki Pancernej i Samochodowej [Military Institute for Armoured and Automotive Technologies], Ośrodek Badawczo-Rozwojowy Urządzeń Mechanicznych sp. z o.o. [Mechanical Devices R&D Centre], Military University of Technology, National Defence University of Warsaw and Warsaw University of Technology.

The agreement concerning the implementation of the Borsuk programme has been concluded back in 2014. According to the said contract, the vehicle, ready for series manufacturing, is to be ready before the end of the year 2019 – the vehicle is to, at that stage, pass the qualification test programme. Relevant documentation shall also be readied for series production. Initially it was expected that the work would be finalized in a 36 months cycle, and this requirement was very difficult to be conformed with. This stage was different from other, comparative programmes pursued abroad, in case of which the final result took about a decade to see the daylight, which much more funds allocated to the projects.

The programme budget has been defined as PLN 75 million. These assets are to make it possible to finalize all of the works, carried out by all of the consortium members. The National Centre for Research and Development provides only 62 million zlotys. The rest of the funds is provided by the industrial members of the consortium. And not all of the said members have been burdened with the risks involved. The Universities and research centres do not have any financial assets invested in the initiative.

Representatives of the HSW facility confirm the fact that “Borsuk” programme’s advancement is significant. We’re doing our thing, and our consortium partners are doing theirs. Things that were possible to be completed, before the facility received the approved, detailed requirements, are being implemented in an ongoing manner – as it was stated by Bartłomiej Zając, Board Member, Director of Development at HSW S.A. The work on transmissions, carried out by BUMAR-Mikilczyce, is quite advanced, WZM Poznań has made some good progress when it comes to the arrangements related to procurement of the powerpack, which is to be realized in line with conditions that would, alongside the interest of the Polish Army, also secure the interest of the Polish industry. We have also, jointly with the military entities and universities, carried out a series of field tests, involving a model of the bottom part of the “Borsuk’s” hull, in order to confirm that the assumed IED protection parameters are conformed with. This gets us closer and closer to the final structural solutions.

The status of work, related to the “Borsuk” IFV has been presented, on 28th June, in front of the members of the Parliamentary National Defence Commission, during its meeting in Stalowa Wola. The officials got themselves acquainted with the video recordings of the process of the field tests carried out by the Military Institute for Armoured and Automotive Technologies, during which explosives were detonated under models of a fragment of the bottom part of the vehicle’s hull.

Currently, two different designs are being tested. Both were developed by the members of the consortium. Analysis of the results of the aforesaid tests is going on at the moment, in order to optimize the design in a way which would make it possible to achieve the best level of IED protection, with the lowest weight of the structure that is achievable. The weight of the whole vehicle has been minimized, also thanks to the fact that composite-rubber tracks are used, instead of steel ones. And this is just the tip of the iceberg, when it comes to weight-saving.

The tests that have been already carried out are a stage of works, the aim of which is to develop the whole design for “Borsuk”, and the next example could be created out of the final, ultimate armour sheets, and it is going to be fitted with the final iteration of the hydro-pneumatic suspension and equipment. It is assumed that the said model would be equipped with one of the turrets created by another, HSW-led consortium, within the scope of the ZSSW-30 programme. This will make it possible to create the test programme, within the scope of traction and amphibious capabilities.

All of the aforesaid works are to be carried out only with the use of a full scale “Borsuk” model, the works on which may be now finished. Works on the 2-million zlotys worth model, which in practical terms would be a pre-prototype of the “Borsuk” vehicle, have been suspended, in anticipation for the basic requirements contained within the tactical and technical assumptions, to be approved. The approval of the requirements which took place at the end of October makes it possible to make further arrangements, regarding the final size of the vehicle. According to the representatives of the HSW facility, this made it possible to restart and initiate the works at full speed.

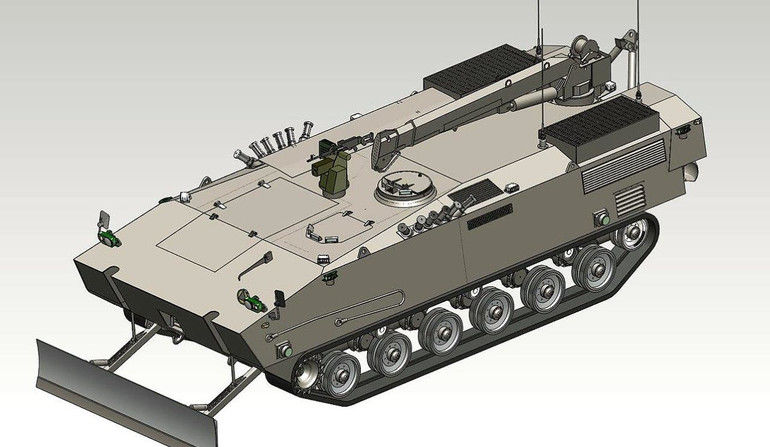

Controlled exposure of the vehicle to explosives is going to take place at the final stage of the aforesaid process. Will additional model built meanwhile be used for that purpose (so that works may be carried out in parallel, on two examples)? Time will tell. So far the R&D portion of the works is treated by the consortium with the highest priority. The design of the bottom part of the new IFV, along with the suspension, is going to have a critical significance for the structure of every other variant of the vehicle: the basic variant (with weight of 25 tonnes, compliant with the requirements issued by the Polish Ministry of Defence), and the heavier variant, with higher level of ballistic protection. The weight of this version is going to exceed 40 tonnes, thus it may be comparable to the heaviest derivative of the Puma IFV which, in its basic variant, weighs around 31.5 tonnes. In comparison with the standard platform, this vehicle will not be required to have amphibious capabilities.

The technical solutions related to the vehicle body, suspension, drivetrain and propulsion system contain a power reserve which would be required, should additional armour be included in the “heavy variant”. The said reserve also makes it possible to implement the autonomous active defence system for the vehicle, along with the battle management suite and option of carrying several Spike ATGMs, cannon and machine gun rounds and “Tytan” infantry combat system for the soldiers inside the vehicle. Moreover, needs related to creation of specialized variants based on the very same tracked chassis are also taken into account, considering the aforesaid developments.

The analysis of the visualizations of the design published so far, as well as the technical information, make it possible to state that “Borsuk” - with the amphibious capacity requirement conformed with – will, in its ultimate form, be reminiscent of the “Puma” IFV (length of 7.33 m, width of 3.4 m, and height of 3.1 m), rather than of the “Ajax” vehicle (6.43 m long, 2.99 m wide and 2.16 m high).

The prospective armament of the Borsuk vehicle, including the remote controlled ZSSW-30 turret, armed with the 30 mm cannon, has been developed within a separate programme. “Hunter-killer” class turret currently undergoes tests, within the scope of the last stage of the qualification test programme. The system has already been integrated with the “Spike” ATGM, and the process has been finalized with live-fire test shots, involving the said missile.

The “Priority Polish Army Modernization Tasks for the years 2017-2019”, document published by the Polish Army’s General Staff back in September, takes into account, within the framework of the operational programme of modernization of the Armoured and Mechanized Forces after 2019, production of a comprehensive family of vehicles based on the Universal Modular Tracked Platform (Uniwersalna Modułowa Platforma Gąsienicowa - UMPG). Besides the Borsuk IFV, the platform will also constitute a base for a tracked armoured carrier (known as “Żuk”), command vehicle (“Oset”), medevac vehicle (“Gotem”), technical support platform (“Gekon”), ABC reconnaissance vehicle (“Ares”), engineering platform (“Jodła”), and tracked variant of the “Rak” mortar (M120G/SMG120).

At HSW S.A., each of the aforesaid programmes is being already planned, with relevant involvement seen on the part of the individual PGZ’s companies and military research institutes. So far, the full scale of IFV needs and tempo of replacement remain unknown.

Unless greater changes take place within the structure of the Polish Army, the Polish military will still include four armoured brigades, five mechanized brigades, one highland infantry brigade, and one coastal defence brigade. The structure of the latter units, and of one of the armoured brigades, is very reminiscent of that of the mechanized elements. Considering the fact that Rosomak APC is a platform which is sufficient for one third of those units, one may be inclined to claim that around 1000 “Borsuk” vehicles are to be manufactured. A variety of sources suggests that 800-1000 IFVs, and up to 800 specialized versions are to roll off the production line.

Representatives of the HSW company note that the Polish industry acts as the Party which has a full decisive power over the technology and the production, development and potential export of the IFV and of the potential specialized derivatives which may be designed and manufactured later on. The officials also note that potential acquisition of a license, in order to manufacture an existing platform, would delay the programme even more. One should take into account the negotiation process, probably also in case of the refined requirements, or the period required to prepare the documentation, establish a network of collaborating companies and production potential, and, last but not least, the time required to integrate the new vehicles with the communication or armament systems. Also the scope of further potential changes, the aim of which would be to develop the product which would remain in the active service throughout the term of 30-40 years, would also be dependent on the provisions of the licence agreement within the scope of modernization, export or design of specialized variants of the vehicle.

Potential selection of a licensed solution would also limit the benefits of reanimating the technical expertise and production capabilities lost by the Polish civil and military enterprises and by the Polish technical universities or research institutes. The above also applies to the capability of carrying out, also in case of multi-faceted collaboration, interdisciplinary and complex military programmes. As it was noted by the representatives of the HSW company, thanks to the “Borsuk” programme, a vast majority of the development works has been carried out in Poland for the first time ever. Similarly as in case of the abandoned “Loara” project, the knowledge could be used to work on other project, forming the valuable capital gathered within the Polish defence sector.

At the moment, the voices suggesting that “Borsuk” programme shall result in creation of a common IFV for the Visegrad Group states, have faded away. Such vehicle would have to meet the requirements of all of the four potential users. At the moment, meeting this condition would be difficult, if not impossible. Never has an attempt been made to create a joint group which would define the requirements, financing scheme and division of R&D and production works, within the scope of such initiative.

We also know that simultaneously with approval of the “Borsuk”-related requirements, the National Centre for Research and Development also confirmed that further research, related to structural solutions to be applied in case of the IFV, would be funded. Further research has already been scheduled by the HSW S.A. company and by the research institutes involved in the programme.

According to the HSW representatives, the process of approving the feasibility study and the of the initial tactical and technical requirements hampered the progress of some of the work, hence the company will not be able to catch up with the delay. Most probably, schedule updates may also be expected, as the original version assumed that the development works were to be finished on 23rd October 2019. At the moment, end of 2019 is indicated as the ultimate deadline for finalizing the project and gaining the readiness for initiation of the series production. This deadline means that the prototype, ready for the factory test programme and for the qualification test programme, must be ready in mid-2018.

The prototype in question will have to take into account the test results related to the pre-prototype (model), which is to be assembled, as it is assumed at HSW S.A., during the first half of 2017. Before the said model vehicle is completed, final two tests will take place, during which the solutions related to the hull bottom will be verified, within the scope of its mine-resistance. Within the framework of the aforesaid tests, fragments of the bottom part of the hull are going to be tested with explosives. Shockwave distribution, deformation of the individual elements of the structure, absorption and attenuation of the explosion, accelerations, pressures and other biomechanical parameters describing the impact of the explosion on the troops inside the carrier, are all going to be measured during the said procedure.

Antoni Macierewicz, Polish Minister of Defence, also got acquainted with the progress of work, and the newly created IFV model. This happened at the HSW facility, on 18th November.

The complete body of the vehicle is to be ready in mid-2017, for static and dynamic test programme at the Institute for Maritime Technology, related to the amphibious capabilities of the Borsuk carrier. Potential corrections and adjustments that would be required following the aforesaid tests will have an impact on the design solutions that would then be implemented in case of the first of the official prototypes.

On 3rd September, 3 years have passed since the moment when the National Centre for Research and Development announced the results of the tender, the aim of which was to select the entity which would develop a new, amphibious IFV. On 24th October, on the other hand, two years have gone by, since the conclusion of the agreement by and between the National Centre for Research and Development and the consortium which was tasked with finalizing the work. Initially, the vehicle ready for production (so with a status including the qualification test programme and development of the mass production documentation) was to be created in 36 months, which, since the very beginning, was a tough goal to achieve, considering the fact that a completely new IFV had to be developed from scratch. After a few months, this deadline has been extended to 60 months.

It is hard to assess the cost of the “Borsuk” IFV programme at the moment. The document developed in March, by the National Council of Development of the Presidential Office, discussing the priority armament programmes of the years 2016-2017, estimates that a single example of the new IFV would have a price-tag of PLN 25 million. Cost of the ZSSW-30 remote controlled turret module would constitute almost 50% of the aforesaid value. The system in question is a subject to a separate programme, in case of which the relevant development works are being carried out by a consortium formed by HSW S.A. and WB Electronics. The very same document assumes that 50 IFVs would be manufactured per annum.

If everything goes well now, and the new IFV is ready for production in 2019, then the deliveries of the first Borsuk vehicles may start in 2021 or 2022.

Jerzy Reszczyński