- WIADOMOŚCI

- ANALIZA

Polish Military Trucks: The Era of Jelcz

Even though quite expansive introduction of the Star heavy duty vehicles took place in the Polish Army, it seems that the future would belong to another brand - Jelcz. All of the above would be caused by a decision made a decade ago.

Jelcz trucks play a crucial role in the process in which the heavy duty vehicles fleet operated by the Polish Army is being modernized. The manufacturing process regarding a variety of types and derivatives of the Jelcz vehicle takes place at the production facility owned by Huta Stalowa Wola (HSW S.A.), which is a part of the Polish Armaments Group. The decision to have the Jelcz manufacturing potential embedded within the structure of HSW has made it possible to save and develop this factory and brand, so famous for its contributions to the domestic automotive industry. Jelcz trucks are being utilized within a myriad of modernization programmes pursued by the Polish Armed Forces. Furthermore, some plans have been made to procure passenger/heavy duty vehicles, produced by the said manufacturer, for the Polish Territorial Defence Forces (WOT) component.

The first automotive programme which has been implemented by the Polish Armed Forces in the post-war period, making use of the domestically developed design solutions, was initiated as early as in 1953. As a result of the above, Star 66: 3-axle, durable and successful design of an offroad truck; has been created. The said vehicle entered production back in the year 1958, with numerous successors being developed along the way, including 660, 266 and 1466 models. The “Star” truck, manufactured by Fabryka Samochodów Ciężarowych (Heavy Duty Vehicle Factory), since the beginning of the 21st Century has also become quite popular among a number of non-military users: fire brigades, energy sector, forestry. The vehicle has also been exported to several countries.

The well-reputed brand has also been a victim to unsuccessful ownership structure changes and strategic errors made by the private investor: Sobiesław Zasada Group. Ultimately, back in the year 1999, the Starachowice-based factory became a part of the MAN AG group, and thus it no longer remained under the Polish control. This was the main reason for the Polish Ministry of Defence to withdraw from collaboration with a partner who remained neither able to provide continuity of deliveries, nor to take the interest of the Polish manufacturers of parts and components into account, within the production process. Collaboration, year by year, was becoming more and more difficult.

Despite the above, and due to the lack of any alternative solutions, up until the period between 2004 and 2005, some armament systems for the Polish Army were being developed on the basis of the Star-brand carriers. Here, the actions undertaken within the scope of modernization of the BM-21M 122 mm rocket launchers, and of the wheeled variant of the scattered mine-laying systems utilizing the solutions implemented in case of the tracked ISM Kroton vehicle based on the MT-LB chassis, both may seem to be a fine example. Both of the systems above were being developed by HSW S.A.

Lack of confidence referring to collaboration with the MAN STAR Trucks & Buses Sp. z o.o company led to a situation, in which an attempt has been made to redesign the systems that were being developed at the time, so that they would be tailored to fit on platforms offered by the second Polish manufacturer of heavy duty vehicles, the factory in Jelcz-Laskowice. Notably, the aforesaid plant has also been going through a crisis related to the economic transformation, which came to an end with bankruptcy of the Jelcz-based facility - this happened at the beginning of 2008.

At the time, HSW SA decided to start collaboration with the Jelcz Komponenty company, which was formed after the formal bankruptcy of Jelcz was announced. The aforesaid entity has been ordered to develop a chassis for a much more advanced variant of the rocket launcher concept - the BM-21M platform. Even though the vehicle, similarly to the version based on the Star platform, has been built around a 3-axle chassis, its overall design was more modern, as it featured a much more spacious, armoured cabin capable of accommodating 6 persons (all of the members of the launcher crew), with extra space available for implementation of a variety of communication, command and reconnaissance systems. Moreover, better handling profile of the P662D.35 chassis has also been a valuable advantage. After the vehicle successfully went through the military qualifications test programme, the aforesaid system, designated as WR40 Langusta, became a part of the inventory of the Polish Army’s Rocket and Artillery Component, in a number of 75 examples.

For the HSW S.A. company, implementation of the aforesaid contract was highly relevant, as it allowed the Stalowa Wola-based entity to obtain the assets required in order to continue the complicated restructuring process within the company, closely monitored by the Polish Industrial Development Agency (the ARP) and by the Government. At the time, the future plans of development were to be concern the Jelcz factory.

Meanwhile, Jelcz facility used the informal investment-driven support provided by HSW to resuscitate itself and focus on other initiatives, pursued for the Armed Forces. Even though in the past, the aforesaid factory specialized itself in manufacturing buses and heavier trucks (including highly reputable “Żubr” vehicles and 315-318 family of trucks), it also had some relevant experience gathered, in the field of manufacturing the vehicles for the military. Usually, the aforesaid platforms came in a form of redesigned variants that were originally destined to be operated on the civil market. JZS-manufactured platforms, and then the ones manufactured by Jelcz-Komponenty, were being used in the Army to create specialized bodyworks, such as e.g. tank-cars.

Three-axle truck was the base model for the Jelcz vehicle family. One may risk stating that in some way the aforesaid vehicles were well embedded within a concept dated back to the 1950s, assuming that such platform should be used to create most of the military vehicle types, both general purpose, as well as specialized ones. The aforesaid layout has been used, e.g. to create the Star 66/660/266/1466 platforms, all of which have played a dominant role in the Polish Army.

Collaboration with HSW has led to a situation, in which the factory based in Lower Silesia began to develop dedicated military platforms with a greater degree of involvement. The specialized requirements defined by the Polish Ministry of Defence were being taken into account as early as at the design stage, in order to properly accommodate military communication systems, protection and reliability-related solutions (central tire inflation system, tyres with ballistic inserts, safeguards for the electric systems, electromagnetic compatibility, etc.).

The aforesaid impulse made it possible to create a family of specialized vehicles, which have been manufactured starting from 2010, the purpose of which was, without any doubts, to be used within the military. Here we are referring to AWA and WA ammunition transport platforms (P.882.53 chassis) for the Regina and Rak artillery systems. In case of the vehicles belonging to the 800 family, with their own weight ranging from 13 to 16.5 tonnes and total weight of up to 35 tonnes, a family of armoured 2-, 4- and 6-person cabins has been designed, with the said cabins having limited height. As a result of the above, a carrier has been developed which offered a great degree of flexibility, within the scope of its purposes and function. 882.53, 882D.43, 862D.43 platforms can be listed among the variants manufactured.

Within that period, the first elements of the first ever design developed and manufactured in Poland from scratch, featuring an 8×8 layout, the Jelcz 800 platform, have been created. It may be stated that the design belonging to this family of trucks was created as a response to expressly defined requirements of the HSW facility, at which, at the beginning of the year 2008, a programme was restarted to develop a self-propelled 155 mm cannon, at the time perceived as integral division fire modules (DMOs), complementing the tracked Krab SPH. The DMO structure also assumed that the Army would be offered with a logistics component, supporting the combat vehicles.

Once the Jelcz facility has been taken over by HSW, the Stalowa Wola based entity became an owner of 100% of the shares of the company located in Lower Silesia. At that time, a family of vehicles utilizing the 600-series chassis was also being intensely developed. These vehicles include more of Rak and Regina support platforms, such AWRU/WRUE technical recovery vehicles/vehicles tasked with repairs of the electronic components (P.662D.35). The carriers of this family have also been used to create combat and support vehicles for the coastal rocket artillery unit, armed with the Kongsberg NSM missiles. The same platform has been used to create the Liwiec weapon tracking radars and MS-20 Daglezja bridges. Furthermore, Jelcz production programme concerning the ‘600’ family includes specialized platforms too, such as fuel tank tractors, or classic high mobility transport vehicles (662D.34, 662D.43, 642D.35, 662D.430P).

2-axle platforms remain a separate area, when it comes to development of the Jelcz vehicles. The Polish military has been scrutinizing an idea to introduce such platforms since mid-1950s. At the time, Star 44 truck was being developed in parallel with the Star 66. Back in 1954, a decision was made, once the prototypes of both models were examined, to end the programme and then all of the workforce was assigned to the process of creating 3-axle, highly mobile trucks, also offering a high degree of offroad capabilities. Nonetheless, the idea to create a twin-axle truck for the military was being repeatedly analyzed from time to time.

The Starachowice-based factory developed a family of Star 244 vehicles in 1975, with 1444 model to finish with (developed in 2008). However, the 1444 was deprived of its Polish roots, being fully developed by the MAN TGM company. After the failure – the 744 twin-axle model – similar designs have not been successful, even in case of the 944 design created back in 1999. The armed variant of this vehicle (NSW .50-cal machine gun being the ordnance) in a 4×4 layout has been created for the Polish units involved in the allied operations in Iraq.

Moreover, Jelcz has also been working on 4×4 trucks for civilian applications. Jelcz 300 and Jelcz 400 families have become a source for 420/422 derivatives, weighing 7-8 tonnes, as well as the 442 platform, quite popular among the Polish firemen.

The development of the aforesaid line of vehicles also led to creation of the 442.28 model, also known as “Bartek”, brought to life back in 2007, constituting a response of the industry to the claims made by the military, suggesting the popular three-axle vehicles would be replaced by a twin-axle platform. The said truck would be tasked with transporting both soldiers, as well as goods. It would also carry out other, specific-purpose missions. Jelcz facility began to fight for the Polish Ministry of Defence’s appreciation for its offer.

The vehicle was characterized by total weight of 15 tonnes, and by an ability to tow trailers as heavy as 12 tonnes. It also featured a carriage-styled armoured cabin. The powerplant came in a form of a 275 HP IVECO engine synchronized with a 9-speed mechanical transmission and transfer case, as well as an inter-axial differential and locking differentials.

A truck, compliant with such assumptions was virtually the first of the proposals prepared by the Jelcz-based company, to be offered in the upcoming competition organized by the Polish Ministry of Defence, the goal of which would be to replace the vehicles used by the military with new generation platforms. The said programme was aimed, primarily, at replacement of the Star 266 vehicles (gradually becoming obsolete), with the secondary objective seen in a delivery of a chassis that could become a universal carrier for specialist bodyworks.

On the basis of the experience gathered during the “Bartek” programme, the Polish Ministry of Defence has prepared more detailed requirements, defining e.g. implementation of a 6-cylinder MTU motor with a power output of 240 kW, 9-speed mechanical gearbox, payload carrying capacity of 6 tonnes with own weight of the vehicle not higher than 9750 kilograms. Furthermore, the new truck was to be compliant with the European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR), equipped with a 70 kN hoist and BEADLOCK inserts in all of the wheels. Finally, the vehicle shall also be able to wade in 1.2 m deep water and be operated within a temperature range from -30 to +50 degrees Celsius.

This required design works to be undertaken, concerning the ultimate 442.32 model, which began back in 2011. Following the experiences gathered when 3-axle trucks were being developed, and after implementation of an innovative 4-axle platform, HSW S.A. and JZS already negotiated the conditions regulating the further collaboration. The goal of the cooperation was to acquire the Jelcz-Komponenty company by HSW, immediately after the civil department of HSW was taken over by the Chinese LiuGong Machinery company. This made it easier for the HSW plant to make significant investments in the technical and process related equipment for the Laskowice facility. Moreover, HSW has also expanded its human resources with educated technicians and engineers. The production capacity has been doubled, reaching 500 vehicles per year, with 500 persons working at the plant.

A prototype of a new truck has been officially presented, under the HSW S.A. brand, in September 2013, during the Kielce MSPO defence exhibition. Two months later, on 29th November, the Armament Inspectorate has concluded an agreement, worth PLN 674 million, concerning the procurement of the first lot of the Jelcz 442.32 vehicles, in order to meet the requirements of the Polish Army. It is expected that procedures that would envisage further orders would also begin. In total, it is estimated that Polish Armed Forces would need up to 7-8 thousand heavy duty vehicles of this class. Jelcz offers them in a variety of versions, differing in the type of cabin, available payload area, equipment specifications and so on.

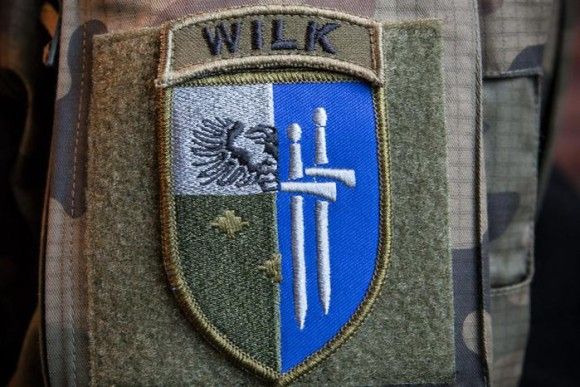

At the beginning of the year 2017, the Armament Inspectorate informed us that there is a plan assuming that medium-size heavy-goods/passenger Jelcz vehicles would be procured for the Territorial Defence component. The vehicles manufactured at the facility which has become a part of HSW a few years ago would also form a core of the inventory package used by the new branch of the Armed Forces.

Design and development works concerning a carrier for a light Kryl self-propelled, wheeled 155 mm howitzers were an entirely new experience, within the framework of collaboration established between HSW and its Jelcz Subsidiary. The requirements imposed by the Polish Ministry of Defence, including the one requiring that it should remain possible that the vehicle is transported onboard the C-130 Hercules airlifter, have forced the collaborating parties to limit the dimensions and weight of the newly developed platform which was still to guarantee good offroad capabilities, high level of ballistic protection and high dynamic strength of the vehicle structure.

A vehicle of an entirely different design has been created, with two-section, lowered cabin, with its engine protruded at the front. Since the autumn of 2014, a prototype of the Kryl self-propelled howitzer has been involved in a military test programme, the goal of which was to make it possible to begin series manufacturing of that vehicle, starting from 2018. The initial quantities of this self-propelled artillery system to be acquired, according to the Polish Ministry of Defence, include, in total, 7 modules, including, in total, 168 units.

HSW and Jelcz also hope to be involved in implementation of programmes strategic for the Polish MoD: Narew, Pilica, Wisła (air defence) and Homar (rocket artillery)

Jerzy Reszczyński