- WIADOMOŚCI

- ANALIZA

“Kryl” Going Through a Renaissance?

Huta Stalowa Wola has accelerated the work on the 155 mm “Kryl” self-propelled howitzer, based on a wheeled platform. Polish Armed Forces have declared that, following the introduction of the “Krab” howitzer, “Kryl” is going to become yet another artillery system, which will make it possible to fully replace the “Gvozdikas” and “Danas”. The manufacturer declares that production readiness may be attained as early as in 2018, however, in order to achieve that, it is highly desirable to define the requirements and carry out a number of formal procedures.

Throughout the last several months, following the self-propelled “Rak” mortar (with procurement agreement signed on 28th April 2016, concerning 8-company-sized “fire modules”), “Regina” system became the main actor of this part of the stage of the Polish Defence industry, related to modernization of the rocket and artillery component of the Army. “Krab” howitzer is the central element of the aforesaid solution. The peak moment of the Regina programme is seen in the contract signed back in December, the value of which is defined as PLN 4.7 billion, and the goal of which was to acquire another four “Squadron Fire Modules”. In the shadow of the aforesaid initiatives, which would result in procurement of 64 “Rak” [Crayfish] 120 mm mortars (by 2019), and another 96 “Krab” [Crab] SPHs (until 2024), another crustacean of the HSW family remained - “Kryl” [Krill] - a howitzer lighter from its tracked cousin, based on the Israeli ATMOS 2000 system and a specially designed 3-axle “Jelcz” chassis.

A prototype of the said cannon, which undoubtedly introduces a new level of quality into the offer of the Polish armament industry, had been premiered when the future of its tracked relative was still being scrutinized. The above does not mean that after the problems with the chassis were solved, and after a contract concerning the “Krab” system was signed, “Kryl” has become less important for the Army. However, still no clear stance was taken, one could even get an impression that the opinions of the Missile and Artillery component of the Polish Army and of the Armament Inspectorate differed, when it came to that matter.

The fact that the programme concerning the wheeled 155 mm SPH is yet again becoming important for the Army has been confirmed by Antoni Macierewicz, Minister of Defence.

“The army has already rekindled its interest in that project.The work will commence” - as it was stated by Antoni Macierewicz, on 18th November 2016, during a press conference finalizing his visit at Huta Stalowa Wola.

The aforesaid declaration was made several days after the Minister had signed the new, updated technical modernization plan, formally crossing out the wheeled SPH programme out of the list. The original modernization plan which was to be pursued between 2013 and 2022 did not even mention “Kryl”. The platform emerged there after the amendments, and it was assumed that the “Kryl” development project which began after an agreement was signed by and between the National Centre for Research and Development and HSW on 28th December 2011, would lead us towards creation of a prototype in 2014, which has been done, and towards finalization of the development project by 27th December 2015. During that year, factory test programme was being pursued, however no specific steps for Kryl have been defined within the period between 2016 and 2017. A silence which was difficult to comprehend was the main thing that could have been witnessed in case of that programme, leaving a lot of space for speculation.

In the initial phase of work of this project it was assumed that the goal would be to acquire 4 units for the brigades which operate the Rosomak vehicle. 24 cannons per a single module. But, when back in 2012 an entry emerged in the technical modernization plan, regarding a new date on which the development work should end - last quarter of 2018 - an acquisition plan has been defined, starting from 2019, of 7 “Kryl” modules, 168 howitzers in total. This weaponry would also cooperate with the brigades equipped with the IFVs. This means that an assumption, in line with which “Gvozdikas” were to be replaced by “Krabs”, and “Danas” were to be replaced by “Kryl”, has evolved.

Such arrangements remained valid, until the moment when October amendments were introduced into the technical modernization plan – initially the programme was removed, but after several days, Macierewicz announced that “Kryl” programme is still on the go. Head of the Polish Armament Inspectorate, Brig. General Adam Duda, who resigned from his position in December, had told us: If the Defence Minister said so, then it means that it would happen so. Brig. general Sławomir Owczarek, who began his service on the position of the head of the Artillery and Missile component of the Army said that such capability is desirable, so that we have a unit like that, on the wheels, which would fill in the gap of the wheeled brigades. It would partially replace the “Gvozdika” howitzers, and “Danas” in a longer run. General admits that he is acquainted with the assumptions of the “Kryl” programme, in line with which the system was to be procured after 2022: As the chief of the Missile and Artillery Forces I would like this to happen as early as possible, but this is not dependent on me...

Up until recently, the position taken by the Ordering Party in relation to “Kryl” was ambiguous. The contractor was focused on finalizing the preparation of the “Rak” mortar and “Regina” SPHs production phase, also waiting for a message from the Ministry that it is becoming interested again in acquisition of a wheeled 155 mm howitzer, with effectiveness and range equivalent to the corresponding parameters of the “Krab” system. The declaration made by the Minister of Defence, quite coherent with the stance exhibited by the artillery units, makes it possible to hope that the “stopping point” between the development work of the National Centre for Research and Development and further development at the Polish Ministry of Defence, would be eradicated.

“Kryl”’ programme has not, so far, been proceeded on the basis of the guidance of the Armament Inspectorate, and clear and official requirements authorized by the Polish Ministry of Defence in line with Decision No. 72. It may be said that in some way, the said initiative exists similarly to a human without a birth certificate. Assuming that both parties - Army and the programme leader - have good intentions, clarification of the formalities could be finalized in no more than a couple of months.

Currently the relevant documentation is being prepared. Updating, supplementing and submitting of the said documents at the Armament Inspectorate is a matter of couple of months. So far, the situation is as follows: since more than 2 years the vehicle has been operable, it is drivable, it shoots, it carries out all of the tasks it was designed to carry out, but still, the military test programme remains impossible to be passed due to procedural reasons. Without confirmed tactical and technical requirements, continuation of the costly research is quite cost-inducing for the manufacturer. The Polish Ministry of Defence could disapprove the research results, on the grounds of the fact that no formal basis for that exists. This is also a hampering factor, making it more difficult to export the “Kryl” howitzer, since this type of armament is quite desirable on the foreign markets.

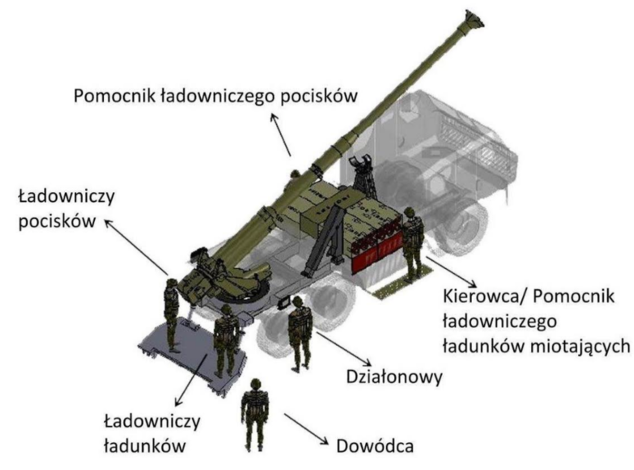

HSW has already arranged, together with the artillery units, an offer of complete “Kryl” squadron modules, both for the artillery regiments, as well as for the general brigades. In its basic assumption made by the Management of the Missile and Artillery Component, this shall serve as a model of fire modules structure, both for the prospective “Homar”’ system, as well as for “Langusta”, also including a complex reconnaissance component, technical support system, medical support, etc.

The road towards development of the “Kryl” system, created back in August 2014, and rolled out in September 2014 during the MSPO exhibition, was far from being smooth. The prelude could have been witnessed during the MSPO 2008 event, when “Caesar” system has been presented by the Nexter Systems company, as a collaboration offer for the Polish Arms Industry, in the process of obtaining a new type of artillery. HSW was the natural collaborator here, since the Polish entity has just begun its works on the “Rak” turret module, and it has also, after 4 years of suspension, reactivated the “Krab” programme which evolved into the form of the “Regina” squadron-sized fire modules programme, with “Krab” placed at its core.

HSW which back then began its collaboration with Nexter Systems within the scope of obtaining the barrels for “Krabs” of the first unit, also got involved in negotiation with the French partner. At the same time, the company also stayed open to the competition proposed by the Israeli Elbit facility, offering the access to the ATMOS 2000 howitzer technology, with barrel length of 52 calibres.

During the initial phase of work, a concept of basing this platform on other designs has been rejected. “Zuzana 2” was also rejected since, similarly as “Dana” it featured an autonomous, closed turret system, associated with the tracked platforms, which to some degree may be a controversial view. Automation of the loading process was the advantage of that option, with weight seen as a disadvantage. FH-77 BW L52 “Archer” system offered by BAe Systems was considered to be too expensive, as it was comparable with acquisition of an equivalent tracked platform. It was assessed that the weight of the product (30 tonnes), range and design with a closed, automated loading system, are not compliant with the requirements of the Polish Army. Moreover, the Poles have assumed that in conditions of real combat, lack of the manual channel may pose a threat in which mission could not be completed, should the complicated loading system become faulty. The later fate of the system, with Norway resigning from procurement of 24 cannons, only confirmed the accuracy of the aforesaid analyses. “Caesar” and ATMOS 2000 could still have been selected back then.

The comparative analysis of both highly advanced, but different designs have shown that the Israeli model had an advantage. Not only was it considered to include a number of better solutions (e.g. different breech), it also had better parameters deciding on the combat features, including a wider scope of operation for the mechanism controlling the cannon.

Even though the French design had a firing elevation range of 0.6 – 67.5 degrees, and azimuth range of 15 degrees (from the longitudinal axis of the carrier, in both directions), in case of the Israeli cannon, the available elevation range was from -2 to +70 degrees and, 25 degrees change was possible in case of the horizontal plane. This is highly important in a situation when it is required to change the target coordinates, since there is no need to change the position of the cannon, or change the firing position. Moreover, Israeli solutions related to the issue of transferring the dynamic load following the shot onto the ground were also considered to be better (better location for the cradle bearing). This has been confirmed by the shooting tests, since rounds shot from “Kryl”, with identical setting, have been hitting the very same point.

Neither of the cannons did offer full automation of the ammunition loading process, as compared to the “Zuzana 2” and “Archer” concepts rejected before.

Contrary to the opinions that are quite common, the automated loading system is not a frequent solution applied in the contemporary large calibre howitzers, especially in case of the wheeled platforms. Slovak solutions are an exception here: “Dana”, “Zuzana” and “Eva” systems, with the latter still surrounded by a bit of mystery. The automatic loader is also present in case of the Russian 2S19 and 2S35 systems, and probably in case of the Serbian NORA B-52 system with a closed turret. “Krab”, AS90, T-155 “Firtina” and K9 “Thunder”, or even PzH 2000 are all fitted with a semi-automatic loading system, mechanizing, not automating the loading process.

The selection of the “Elbit’s” offer has also been motivated by business criteria. The Israelis also did not force Poland to adopt the whole offer, including the platform. The Poles, since the very beginning, wanted the carrier to be developed domestically which, worryingly, seemed to be similar to the AS90 system and the “Krab” platform fate. Elbit has been much more flexible, when it came to the industrial collaboration. Thanks to the above, it was possible to arrange a number of solutions which turned out to be advantageous for Poland.

When the contract was being negotiated, no certainty existed, when it came to the ambitious plan of modernizing and expanding the Stalowa Wola’s barrel production facility, so that it would obtain an ability to manufacture 155 mm, 52 calibre-long barrels. At the moment, HSW still has a choice, when it comes to production of the whole cannon, or solely of its cradle system, or whether solely the barrel and breech would be manufactured at HSW.

The production orders portfolio of the HSW, related to the artillery systems, is being constantly expanded, it may turn out that inclusion of the “Kryl” barrels in that portfolio may require more effort, also within the scope of investment, not only within the scope of organization. As we know, 8 company-sized “Rak” fire units will be in production until the year 2019, “Krab” production process, regarding the 4 modules, is being accelerated - it is to last until 2024. Starting from 2019 or 2020, ZSSW-30 turret systems are to enter production, while as of 2020 or 2021, a new IFV is going to enter the production stage, if we do not witness a significant delayy concerning the “Borsuk” programme. At the beginning of 2017, mechanical processing began in the part of the barrel manufacturing facility responsible for the barrels of the largest calibres. This period also confirms the assumptions pertaining to the processing systems of that facility. The barrels manufactured in Poland are going to be received by “Krab” systems of the second Squadron Fire Module unit. Even though the “Krab” turrets, along with the components of the cannon, have been manufactured at HSW, the barrels were being imported. Initially they were being delivered by Nexter systems, and then, by Rheinmetall.

We do not know when, and how many M120G tracked “Rak” mortars are going to be procured by the Army within the relevant contracts. This will entail continuation of production process of the 120 mm mortar barrels beyond the year 2019. It still remains unclear whether, within the framework of “polonizing” the Leopard main battle tanks, Polish Ministry of Defence decides to establish a manufacturing capability concerning the barrels for that platform domestically, at the HSW facility. The acquisition of a relevant license still remains an open issue too. We also have no knowledge when it comes to the plans made by the Polish Ministry of Defence, regarding the equipment for the territorial defence units, in case of which M98 and M120 conventional mortars are being offered by HSW, along with a new Nexter Systems 105 mm LG1 Mk III cannon, some elements of which are already being manufactured in Stalowa Wola. More questions emerge when it comes to the HSW’s involvement in the production process related to the KDA35 cannons for the Navy and rocket launchers and other components of the “Homar” and “Wisła” programmes.

Each of the aforesaid projects will impose more workload on the HSW SA production capabilities, especially on the barrel manufacturing facility, one of the three of this kind in Europe. Despite that, the readiness to begin series manufacturing of “Kryl” which has passed the qualification tests already may be announced as early as at the beginning of 2018.

All of the speculation above, referring to the “Kryl” manufacturing phase, seems to look like counting chickens before they hatch, taking into the account some issues that need to be brought to order at the current stage.

“Kryl” has been founded on an assumption that it shall be air-mobile, meaning that C-130 Hercules aircraft should be capable of transporting the system. Most probably, the aforesaid requirement has been formed under the pressure of the experiences gathered during foreign deployments, throughout which “Dana” howitzers have proven to be very useful. They have been delivered to the Afghan theatre with conventional means of transport. It has been determined then than the potential successor must offer an option of being deployed by air. It has also been shown that “Caesar” howitzer meets the said requirement, which has not been fully verified. Moreover, unofficial speculation suggests that the stabilizing blade and ammunition storages are removed and transported onboard a separate aircraft. This has been confirmed by the crews of the Polish C-130 planes, who have witnessed the process in which the French howitzers were being unloaded. Nevertheless, a requirement has been set to transport the system with the use of the Hercules. This meant that there was a need to contain the size and weight of the howitzer within a limited envelope (maximum weight of 20 tonnes - which is the payload of the C-130).

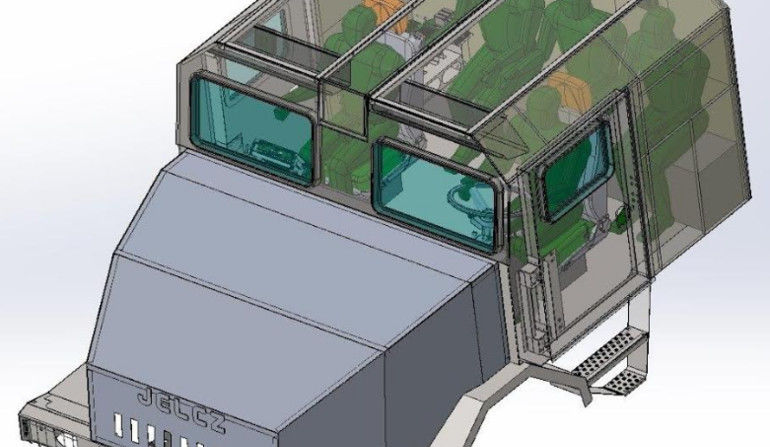

At the very beginning, this imposed a number of limitations on the designers, which was reminiscent of the conditions met by the “Borsuk” IFV’s design team. Meeting the mutually exclusive requirements means that either a compromise must be created, or non-standard solutions must be implemented. For “Kryl”, this meant that transported mass could not exceed 19 tonnes. At the same time, relevant requirements concerning the ballistic protection of the cabin also had to be met.

The only option to achieve that goal has been seen in designing the chassis from scratch, with fixed parameters of the cannon and its frame, resulting from its structural properties. Elbit has diminished the weight of the cannon by 500 kilograms, down to 9.5 tonnes, to meet the Polish needs. The chassis, in order to meet the weight requirement (9.5 tonnes) also had to include a number of non-standard solutions, utilizing, among other elements, new materials,, making it possible to attain the lowest weight possible, with the required strength maintained. In case of the wheeled SPH, one had to take into account the extreme dynamic load caused by firing the cannon with a full charge.

The designers, as an effect of the effort above, have rolled out, on 17th July 2014, a new Jelcz 663.28 chassis with MTU 6R106TD engine (326 HP power output), with a mechanical (option of using a fully automatic one) ZF transmission (9+1) For the first time ever, Jelcz has been creating a vehicle which from the very beginning was designed for a military purpose. The design process involved, among other entities: Military University of Technology, Wrocław University of Technology, as well as Elbit.

For the first time in case of the Jelcz cars, the engine block is protruded and placed in front of the front axle. This made it possible to improve the weight distribution, imposing a greater load onto the steerable axle, on the other hand – the cabin became lower, thanks to that. For the purpose of saving weight, the engine cover has been created out of plastics, which was a mistake. Even though the weight of the system was lower, the handling properties offroad were worsened, when it came to the steering properties related to the front wheels – hence, more load had to be imposed at the front.

The traction problems have been solved, the vehicle has its performance conforming with the requirements, both when the ammunition remains onboard (18 rounds, but more may be carried - there is still more performance envelope available), as well as when the rounds are used up.

“Kryl” is capable of attaining speeds of 90 kph on the road, which is equivalent to the parameters of the mechanized brigades’ “Rosomak” family vehicles. And it is these vehicles that are to be the main platform with which the Kryl howitzer should cooperate. Offroad performance is sufficient not to hamper the speed of movement of the group, range has been defined as 500 kilometres (640 km is the target range), with two full fuel tanks. The howitzer may be driven along 20 degree slopes (longitudinally and in a traverse manner) and over 30 degree slopes, ditches, thresholds, it may also wade in water up to 1.2 meters deep. Central tyre pumping system has also been fitted on the platform, guaranteeing its mobility should the tyres be shot. Moreover, the system also regulates the vehicle height and clearance, which is defined as no less than 0.38 m. For the 5-persons crew - ultimately the vehicle is to be used by a crew of 6, an armoured cabin is provided, which may receive extra protection in a form of additional panels. The cabin has been fitted with an A/C system with filters, it is separated from the engine compartment with a sealed bulkhead, it also features a hatch in the roof part.

The initial operational requirements for the development work did not include any conditions related to passive protection measures, such as laser warning receivers or smoke grenade dispensers. IED and mine protection levels also have not been defined. It seems unlikely that such cannon would be operated in an unknown area, in direct contact with the enemy, hence the above is not a surprise. “Kryl” has been required to tow a trailer, with maximum mass of 2000 kilograms. At maximum permissible weight, the howitzer may, without any limitations, use public roads, bridges and overpasses. The maximum permissible vehicle width without the mirrors - 2.44 meters, maximum height (lower than in case of e.g. “Ceasar”) is 3.44 meters, total length is 10.3 meters.

C-130 loading process has been successful, even though some problems within that scope emerged. However, once the said condition has been met, the air-mobility requirement was relaxed. This ability has not been resigned from completely, but doubtful condition of tailoring the system to be carried by a specific airlifter has been taken out of the equation (similar condition has been implemented in case of the Stryker APC). C-130 would be capable to carry Kryl, however, its operational range would be drastically limited. Even though, the howitzer may be transported by Hercules, after several conditions are met.

The whole fire control system is compatible with the equivalent solutions utilized in case of other ordnance utilized, or planned to be utilized by the Polish artillery units. We know that the said systems are based on the most advanced solutions in the world, resulting from a long term and effective collaboration between HSW and WB Electronics. Thanks to the above, which is, with a high degree of satisfaction, being confirmed both by the designers, as well as by the users, should an emergency arise, any other “Krab” crew could operate the “Kryl” howitzer, in an intuitive manner. This has been achieved thanks to the “Topaz” software, implemented in case of all artillery assets within the Polish Armed Forces.

The electronic and ICT equipment of the “Kryl” howitzer includes, among other solutions, FONET communications suite, digital radio, MRVS 700 SCD muzzle velocity radar, TALIN 5000 INS/GPS system with an odometer, ballistic computer and artillery computer. The fire control and command systems have been automated to a high degree. The data coming from the command centre may be processed immediately, even when the crew is outside of the vehicle. This accelerates the firing solution data exchange process. Should the automated targeting system be damaged, the gunner may use instruments allowing for manual operation.

When the mission is being carried out, the whole crew stays outside of the vehicle, at positions which are strictly defined, at which not all of the crew members maintain visual contact among themselves and with the commander. Thus the crew also communicates via radio headsets. Entering and exiting the cabin is very efficient. Moreover, the time required to leave the firing position is not longer than several seconds from the last shot. Within the context of the requirements concerning the time required to change the firing position, fitting the Kryl howitzer with the APU unit is controversial. For the reaction time, it is highly important that the engine of the vehicle remains active when the weapon is fired, to make rapid evasion possible, thus APU seems like a redundant element of dubious relevance. Using an APU of proper power is pointless, since there is no space, it creates extra weight and cost and only minor fuel savings, as compared with the main engine, with insignificant reduction of the thermal signature.

“Kryl”, similarly as “Krab”, may use any ammunition compliant with the JBMoU memorandum, and the very same propelling charges. From the logistical point of view, this is very significant, but often unappreciated. So far, Polish Ministry of Defence has not revealed the APR precision rounds requirements, but one may speculate that such needs are obvious, even though they have not been officially formulated.

Kryl’s cannon range is defined as 5 to 40 kilometres. Rate of fire of 6 rounds per minute was achievable by the factory crew at HSW. It may be increased significantly by a well-trained military personnel. In case of suspended fire, the rate of fire is two rounds per minute. Naturally, the software is compliant with the MRSI system. “Kryl” has successfully passed the low temperature tests.

In numerous discussions relating to the howitzer, lack of an automated loading system is defined as the main disadvantage of this design. The condition of fitting the howitzer with an automated system later is sometimes brought up by the military. Thus, it has almost a mythical value, having a decisive impact on the Kryl’s combat abilities or lack thereof.

This solution, as mentioned above, is very rare in other designs. Since the very beginning, should an automated loading system be implemented, such design is developed to provide full loading automation. One of the imperative conditions is to connect the loading mechanism for the round and the propellant with the magazine for rounds and propelling charges, and an igniter feed.

This means that the number of charges available for immediate use remains limited. Every stage of the process needs to be monitored by a computer, the purpose of which is to manage the modular propelling charges and deliver a proper number of charges, without any interference required on the part of the crew, depending on the firing solution, range, trajectory, and so on. This is, obviously, feasible, if the cannon is designed around the autoloader, at the very beginning of the development process.

Is it possible to design such system for “Kryl”, based on ATMOS 2000? The representatives of HSW unanimously state that without redesigning the whole cannon section, this would be infeasible. The complete redesign would have consequences, and it would entail the need of redesigning of the chassis, in order to take into account the unavoidable change of the weight distribution or the cradle system shape. For the whole programme, this would form a fundamental need to increase the effort, with dubious certainty of the success, should work within that scope be undertaken. Here, only after years of development and expenditure, one could learn if the effort was worth it, even when an option of procuring a license for a ready design of that kind, such as “Eva” would be pursued - “Eva” is still being developed.

The issue becomes clearer, when one precisely defines the “autoloader” as a mechanized feed system, even though such solution does not relieve the loaders from loading the cannon. In case of Kryl, such solution is feasible. Still, a question remains, whether it would be reasonable, and what costs would be entailed. Elbit company has a ready-made automated loading mechanism design at its disposal. It is based on the ATHOS 2000 towed howitzer solutions. The operation of the system is based on raising the round to the height of the breech, and coordinating the position of the loading channel with the barrel. Then, the ammunition is fed in two stages. First, the round is loaded, with the propellant charge to follow. As in case of this solution, a conventional loading channel does not exist, the round should be placed directly in the breech and fed with the use of a manual feed.

The mechanical feed system in case of the “Ceasar” cannon is of different design, as the round is placed onto the channel located to the left side of the breech, and then an arm raises the channel up to the barrel level and feeds in the round. This solution has similar disadvantages and also has no impact on increased rate of fire. Should the loading system be damaged, loading the cannon is difficult without a conventional loading channel, and the round must be fed into the breech manually. The round weighs 50 kilograms, and handling it without an option of supporting it on a channel is quite difficult and dangerous in intense combat. In such situation, more loaders would be required, which renders the automated system useless.

In both cases, this reduces the workload imposed on the crew and makes the conditions available more comfortable. However, as mentioned, the said solution increases the potential risk of damage, and emergence of high consequential costs. For the manufacturer the aforesaid ramification has no significant meaning. The situation is different in case of the Ordering -Party, covering the cost mentioned above. The representatives of the HSW facility also point to relevant advantages of the current solutions, namely, it is reliable, cost-effective, and errors are difficult to be made, should it be applied.

Brig. general Sławomir Owczarzak claims that the Army would still require HSW to implement more automated solutions in case of Kryl. Such requirement is easy to be understood if one observes the howitzer being fired at low elevation settings, when the chamber is located in the highest position, as compared to the operator’s deck on the blade.

An interesting response to that requirement has been prepared at HSW/WB Electronics. Within a few weeks, it is possible to modify the fire control system and “Topaz” software, in a way which would make the loading process much more efficient. This solution is only applied within the software of the fire control system, it is reversible, and it would have no impact on the current design and configuration of the cannon, or on the maintenance conditions, it would also not entail any cost related to expansion and further complication of the design Should the current solution face a fault, the system moves along with the cannon which has a redundant control system. Meanwhile malfunction of the currently applied hydraulic ammunition feed does not make it impossible to control the cannon, since the “loading channel” still makes it easier for the crew to place the round inside the barrel. Acceptance of this solution by the Army still remains an open issue.

The progress of work on the programme, and introduction the “Kryl” howitzer into the inventory of the Polish Army is also an object of interest of the Israeli partner of the HSW facility. The Israeli company declares that it would get involved in acquisition of foreign buyers, should the works on the howitzer be completed. The interest is quite significant, also outside Europe. Both HSW, as well as Elbit, see introduction of Kryl into the inventory of the Polish army as an important argument, related to the export initiatives that could follow.

Up until now, the National Centre for Research and Development provided an amount of PLN 28 million to finance the Kryl programme. HSW has made its own contribution too.

Jerzy Reszczyński