- WIADOMOŚCI

- ANALIZA

How to build resilient supply chains in an era of high risk?

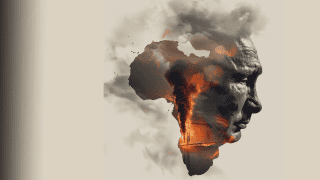

Since the beginning of the full-scale war in Ukraine, the topic of disrupted supply chains has been a recurring one. The enemy attacks them to deprive defenders of the equipment they need to fight and civilians of what they need to survive. This isn’t just a matter of military logistics. It’s also an attempt to break society’s morale.

A supply chain is the path a product takes from raw material to consumer. It’s the people, places, and processes that make a product possible and deliver it on time. It’s its „route of travel”: from mines, smelters, fields, or factories to the hands of the user.

For simple products, the supply chain is short and transparent. For complex equipment, such as combat vehicles or cars, however, an extensive network of interconnected paths emerges – separate for each component, such as a radio, engine, or wheels. Each path has its own length and level of complexity, but together they form a system that enables the creation of the final product and its delivery to the customer.

Threat architecture

Today’s supply chain risk ecosystem is multidimensional, highly interconnected, and susceptible to disruptions that cascade. Globalization is shifting the focus from the logic of efficiency to the logic of resilience. Supply chains are becoming not just a part of logistics, but an element of economic security.

Contemporary supply chains resemble supply lines running through difficult terrain. One weak link is enough for the entire chain to cease functioning. Critical points are not theoretical. NATO calls them „critical vulnerabilities.” These are places where business operates like a column on the front line. If someone strikes the weakest point, equipment and people will not move forward.

The most obvious risk is dependence on a single supplier. In civilian life, this is „procurement risk.” In the military, a single supply route is always a potential trap. When a factory shuts down, a port is blocked, or politics changes course, the entire supply chain grinds to a halt. That’s why diversification is so important, for example in oil supplies. The second threat is bottlenecks: canals, straits, ports, and railway junctions. Today, they serve as ancient bridges on battlefields. One breakdown or bottleneck and thousands of kilometers of chain „freeze” like a front without ammunition.

The length of the chain isn’t the problem in itself. The problem is excessive fragmentation and the number of points of attack. Businesses operate like armies operating in multiple directions. Every supplier, every country, and every procedure poses additional exposure. The most dangerous threats aren’t sudden disasters, but chronic delays that gradually dismantle logistics. If delivery times suddenly triple, the entire system will gradually come to a standstill.

The belief in „zero inventory” increases risk. This only works in peacetime. Under pressure, one delay and the entire system collapses. It’s like sending a unit on a mission without reserves of ammunition, food, or fuel.

Another threat is the concentration of production in a single region. When most of a key component comes from a single source, it’s not efficiency, but a systemic weakness. It’s like basing equipment on a single fuel base. One earthquake, flood, blockade, or sanction is enough to keep everyone waiting.

The most treacherous are the critical points hidden deep in the chain. Companies know their suppliers, but rarely know their suppliers« suppliers. These are where „mines” can lie, detonating without warning.

The lack of alternative routes and contingency plans is a recipe for failure. Often, one failure is enough to leave no reserves to maintain supply lines. Cyberattacks further exacerbate the risk. This is a new, silent theater of operations, but just as dangerous as a strike on a fuel depot, because a compromised supply chain can „go dark” in a minute. The biggest problem, however, is operating „in the fog,” without sufficient knowledge of the situation, when we don’t know where the enemy is, what their intentions are, what threats will emerge next, and even our own capabilities are difficult to assess. Lack of reconnaissance and situational awareness leads to strategic blindness. It seems calm, but this is an illusion. When a threat manifests, options for action are drastically limited. The lack of information leads to a false sense of security. Once the threat becomes visible (the beginning of a crisis/conflict), there is no time to react. Repositioning forces, preparing defenses, or evacuating requires time that no longer exists. That’s why scenarios, contingency plans, and procedures are so important.

An "Ecosystem" of disruptions

Modern supply chains operate in a more complex environment than ever. Risks are compounding, creating cascades of disruptions. Geopolitics is returning to the forefront. Conflicts from Ukraine to the Red Sea are impacting costs, routes, and delivery times. The world is shifting to friendshoring, where production and purchases are relocated to countries considered stable and predictable. Sanctions and export restrictions fragment trade. Meanwhile, key straits and canals are becoming strategic chokepoints.

The cyberthreats mentioned earlier are now commonplace. Attacks on ports, logistics, and production systems can paralyze entire industries. Chains are long, multi-layered, and opaque. The failure of a single entity triggers a domino effect. The importance of digital transparency and the creation of „digital twins” that allow for the analysis of disruption scenarios is growing.

Economic risks are also growing; energy prices are rising, transportation is unstable, and infrastructure is overloaded. There is a shortage of people to perform often simple tasks. For example, there is a shortage of drivers and equipment operators, who may also be drafted into the Territorial Defence Forces or the military. The military will not be able to provide assistance during wartime because it will have other tasks.

Moreover, regulations are multiplying faster than companies« ability to implement them. Environmental, social, and technical requirements are increasing costs and forcing changes in operations. Therefore, deregulation during a crisis can be crucial.

Infrastructure failures, strikes, staff shortages, and overloaded networks are also a factor. Climate is also becoming a constraint. Extreme events are blocking ports, airports, and factories. „Climate bottlenecks” are becoming a real operating cost.

All this makes supply chains a strategic space for economic security, not just a technical logistical process.

How to build a supply chain that doesn't break

Building a supply chain that does not break at the first crisis requires thinking about the economy as an organism, not a collection of separate companies and institutions. Modern supply is a web of dependencies. Companies are linked to transport and energy infrastructure, which in turn is linked to government systems, digital technologies, and the global flow of goods. No one can cope alone these days. Therefore, resilience can only be built through cooperation.

One of the most promising models is a public-private partnership, in which the state and businesses share not only costs but also risks. Joint investment in ports, warehouses, terminals, and IT systems makes infrastructure less vulnerable to crises. Companies would gain operational stability, and the state would gain a guarantee that crucial supplies would not be interrupted in emergency situations. The problem is that in Poland, we still view such partnerships with caution. The joint involvement of the state and private entrepreneurs is more often perceived as a burden than as a tool for building economic security. This is likely a remnant of the mentality of the old system, in which private initiative was treated with distrust, and sometimes even as a clever way of circumventing the rules.

The second pillar could be shared data systems and logistics centers, where various entities, from port operators to public services and companies, share information about what’s happening in supply chains. This ensures everyone has a common picture of the situation and can react before a minor warning sign turns into a major crisis. In modern logistics, information is what shortens response times and helps stop problems before they escalate.

It would be worthwhile to establish permanent „resilience councils,” multi-sector teams operating as a joint crisis management team. This isn’t about local crisis response teams within local governments. Such councils should include representatives from business, administration, transportation, energy, and cybersecurity. Their task would be to constantly monitor risks, develop scenarios, and coordinate actions in unforeseen situations, such as a cyberattack, strike, or power outage. This role could be played by both national organizations, such as the National Chamber of Commerce, and industry-specific or regional chambers that are well-versed in the needs of local businesses. Perhaps such councils already exist, and I’m unnecessarily reinventing the wheel.

The final, but equally important, area is joint investment in the production of critical resources - those elements without which industry, the energy sector, and the healthcare sector cannot function. Batteries, pharmaceuticals, and selected electronic components are just a few examples that could become a strategic weakness if we rely solely on supplies from regions prone to political tensions or natural disasters. Joint production offers an opportunity to become independent from risks that grow with global turbulence.

All these activities should be united by one idea: Resilience is not the product of a single company or institution. It is a common good that requires the sharing of resources, knowledge, and responsibility. Only in such a model can the entire system, not just its fragments, withstand the pressure. And pressure in the modern world will only increase.

Priorities for thinking ahead of crises

What should be most important for decision-makers and entrepreneurs today in building a resilient supply system? Above all, we need to see better, react faster, and wisely secure key processes. A complete picture of the situation across the entire supply chain is essential. Many crises begin with small signals that get lost in the information noise. Companies and public institutions should work together to develop monitoring systems, data exchange, and platforms that show real-time information about what’s happening in ports, railways, suppliers, and warehouses.

Another priority is resilient infrastructure. Ports, terminals, rail networks, and logistics centers must withstand overloads, extreme weather conditions, and cyber threats. Public-private collaboration can yield the best results here. The state provides the framework and security, while businesses contribute technology and know-how.

Cybersecurity is a key element today. The supply chain is digital, so the weakest link can be a small subcontractor or an outdated system. Common standards and rapid incident response are essential.

Buffers and diversification are also important. Companies should move away from the „just-in-time” model and build minimal inventories, alternative routes, and diverse supply sources. Governments, in turn, should support local production of critical components. However, the most important factors are the people and the procedures they must use. No technology will help if teams don’t know how to respond. Regular exercises, simulations, and prepared scenarios are the foundation of economic security today.

In short: monitoring, infrastructure, cybersecurity, diversification, and preparedness are the five pillars that truly strengthen supply chain resilience.

Smart business before damage: Resilience as a competitive advantage

Operational resilience doesn’t have to cost a fortune. Today, it’s the key to competitiveness and efficiency. How can you build it?

First, let’s stop thinking about resilience as a contingency cost. It’s an investment in competitive advantage. Better data, automation, and prediction allow us to act faster and more cost-effectively. You don’t need to stockpile vast inventories to protect your company. Resilience is built through strategic buffers and flexible mechanisms. The system must be able to respond quickly to shocks.

Another element is a complete picture of the supply chain. Companies that know their suppliers at multiple levels respond faster to disruptions. They avoid expensive express transport and manage inventory better. Resilience in this sense reduces costs.

Intelligent diversification is also important. Having several suppliers in different regions, integrated into a single network of data and contracts, ensures security without chaos. It also provides greater negotiating power.

Automation and digitization are helpful. Robots, digital twins, and predictive demand planning stabilize processes and reduce expenses.

Finally, flexibility and collaboration. Companies should efficiently switch supply chains and share the costs of resilience with partners, logistics operators, and even competitors.

Perceptions need to change. Operational resilience isn’t a cost. It’s a strategy and a business shield. Thanks to data, automation, flexibility, and collaboration, companies are protecting themselves, reducing expenses, and responding faster to market changes.

Conclusion

Supply chains are and will continue to be under attack - literally and figuratively. Crises don’t wait. Only those who are prepared will survive. This is a new frontline, not just for the military or defense companies.

They must be strengthened before the enemy forces us to react. Resilience is a shield, and its absence is a death sentence. There is no longer time for naivety.

Almost no supply chain is secure by itself. It only becomes secure when everyone - businesspeople, employees, and politicians - takes collective action. Surprise is a luxury no one can afford.

Supply chain resilience is today a weapon of mass survival. It’s not a choice, it’s a necessity.

Author: Dr. Andrzej Fałkowski, Lieutenant General (Ret.), former Deputy Chief of Defence of the Polish Armed Forces.