- WIADOMOŚCI

Polish PIAP Satellite Gripping Device Tested at ESA

ESA Robotic Laboratory, which simulates condition of weightlessness, has finalized a test campaign which concerned the gripper, the purpose of which is to intercept the faulty satellites remaining in the outer space. The above means that Polish Industrial Research Institute for Automation and Measurements has completed its work related to the e.Deorbit mission.

The issue of space debris, year by year, is becoming more and more important among a variety of actors conducting their work in the space sector, which is especially pronounced in case of the European Commission and the European Space Agency. The latter organ, recently, initiated a special “Clean Space” programme, the goal of which is to coordinate development of a wide spectrum of technologies which would diminish or even stop emergence and the alarmingly growing presence of the outer space debris.

The E.Deorbit mission is the flagship initiative implemented within the scope of the “Clean Space” programme. During the year 2023, a servicing satellite is going to be sent into a low orbit. The instrument will be tasked with intercepting and eradicating the largest observation satellite ever to have been built, which has been inoperable since 2012 - here we are making a reference to the Envisat platform. This satellite weighs more than 8 tonnes.

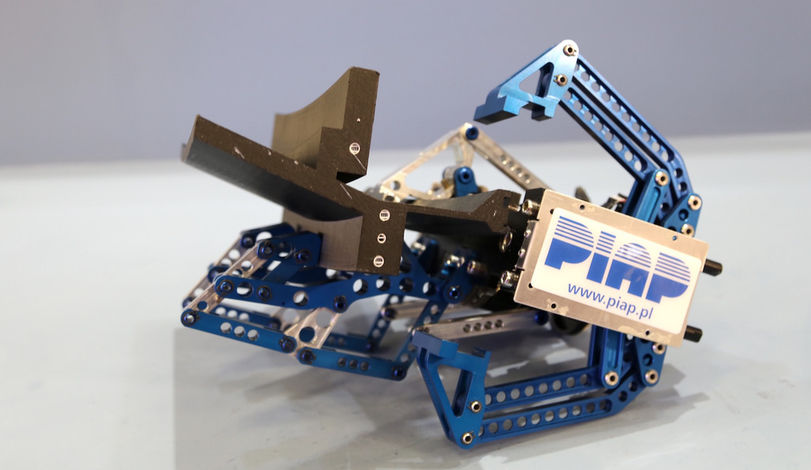

One of the key stages of the e.Deorbit initiative is the maneuver of approaching and intercepting the aforesaid satellite. Due to the fact that Envisat has been fitted with very large solar panels and is rotating in an uncontrollable manner, proper intercept poses a significant challenge. The key feature of the intercepting device is its speed and high tolerance to positioning errors of the mechanism. Both abilities remain at disposal of the gripper designed by the Polish Industrial Research Institute for Automation and Measurements.

Each and every satellite: Envisat, telecommunications or navigation satellites; is covered on the outside by a number of different devices, antennas, cameras, photovoltaic cells. Additionally, the satellites are also covered with the thermal insulation material. This diminishes the number of points which could be potentially grabbed by the gripper. Fortunately, each of the larger satellites also features a so called adapter which makes it possible to attach it to the launch vehicle. Our gripping device uses this very element to catch the satellite remaining in the space. Moreover, which is of key importance for the e.Deorbit mission, as well as for its successors, the satellite may be gripped very quickly, with major errors emerging within the scope of the relative position of the adapter and the gripper. The gripper is characterized by a high gripping power, which is of key importance for further maneuvers, when the servicing satellite remains in connection with the intercepted instrument, and when it makes an attempt at changing the orbit of the set, the gripper, along with its arm, serves a purpose of transferring the loads from the deorbiting motor onto the serviced satellite.

At the laboratory located at the ESA ESTEC laboratory in Noordwijk, the functionality and operation of the Industrial Research Institute for Automation and Measurements Gripper has been, in detail, assessed by the experts working in the field of space robotics and by those tied to the e.Deorbit initiative. On the surface, the friction factor of which is low and the flatness of which is high, two platforms were placed on an air cushion, which partially replicated the conditions of weightlessness. One of the platforms, simulating the interceptor, featured the gripper, while the other, replicating the behaviour of the faulty satellite, featured the adapter ring. With a variety of configurations, scope and conditions, within which the gripper was able to intercept the target, different operational scenarios were analysed and verified.

When talking about the technology of the e.Deorbit mission gripper, it is worth to mention the fact that the very same technology will soon be applied in the market areas that are way more interesting, including the process of carrying out orbital maintenance of the satellites, refuelling them, and applying a variety of methods that could be used in order to prolong the satellite’s operational lifetime. It is going to be a new market segment, and Industrial Research Institute for Automation and Measurements is getting ready to enter that area.

The gripper design has been developed and created within the Polish Industry Incentive Scheme.