- WIADOMOŚCI

Britain builds defence supply chain without China

Securing a lifeline for defence-industry critical elements to break China’s chokehold.

”The Middle East has oil and China has rare earths” - the late Chinese leader Deng Xiaoping* on a visit to Inner Mongolia in 1992.

The realm of modern defence capabilities has accelerated almost exponentially in recent times. Things that were once imagined as almost in the realm of science fiction have now become common specifications and standards within complex military systems. The key factor enabling this ongoing technological revolution has been the availability of Rare Earth Metals (REM) in advanced components, without which it would be impossible to produce the hardware upon which we have become so reliant. The reality is that the collective West has become utterly dependent upon one major supplier, China, which is currently a strategic rival and one day could become an actual adversary in conflict.

China has had a long-term strategy since a long time back of hooking the West through cheap State-subsidised REM production which has ensured not only dominance but Western dependency. It should be stated from the outset that this collective strategic and political failure to grasp what should have been to all levels and agencies of Western governments an obvious long-term danger, must now be mitigated before a situation develops in which the Western defence sector cannot access its critical components.

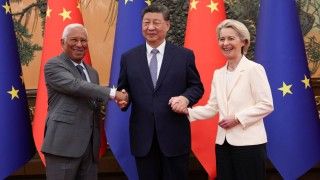

As has already happened, China has begun exercising the tightening of controls over the supply of rare earth metals to the whole West. In response to US tariffs imposed by President Trump in April 2025, China hit back by introducing strict controls of the sale to any foreign country of the main rare earth metals which are particularly critical in US/Western defence systems. This was followed by a more general restriction in October 2025, although with an agreed moratorium for implementation until November 2026.

What are possible solutions to this military-industrial existential threat?

In terms of processing, there are three key parts to the separation and isolation of the target Rare Earth Metals:

Upstream – Mining ore and extraction from concentrates.

Midstream- separation of oxides and conversion into metals/master alloys. Downstream which is the production of specific magnets and components.

Of all these three, it is the midstream process that presents the greatest challenge to scale and develop outside of China, but it is the process that is most crucially decisive for the West to have any defence industry autonomy at all. When the midstream will be fully safe in allied hands, then defence buyers will get guaranteed REM market access, shorter product delivery times and most importantly a supply that will finally not be dependent upon uncertain Chinese foreign export licences.

Why are Rare Earth Metals now a defence imperative?

Permanent magnets and specialty alloys underwrite all of today’s high‑end combat power. This includes a whole spectrum including fast‑jet engine actuators, high‑temperature sensors, naval propulsion, precision guidance, secure communications and advanced radar systems. Neodymium‑iron‑boron (NdFeB) magnets offer unmatched power density for motors and actuators whilst samarium‑cobalt (SmCo) magnets, which retain performance at high temperatures, are crucial in aviation and missile applications.

The simple truth is that with the concerning statistic of 90% of the Rare Earth metal processing production in the hands of the Chinese, alternative solutions must now be sought at this „eleventh hour” or else this creates a single point of failure for Western defence programs when export controls or licensing delays will inevitably happen. The UK’s policymaking and scientific community has also flagged this capability deficit and is calling for domestic midstream capability as demand rises through 2030 and beyond. Within this global context, the UK has thus begun rebuilding the all-important midstream capability to secure magnets and materials vital to produce all its air, naval, land and C4ISR systems.

The UK's Midstream Rebuild: Who matters and why?

This reset essentially revolves around three core British companies Less Common Metals, Ionic Technologies, Metalysis as well as associated allied Research and Development taking place in the UK.

Less Common Metals (LCM): Britain's linchpin for defence‑grade alloys

LCM has just been headlined in a recent report by The Daily Telegraph (24/12/25) as the »tiny British company that outsmarted Xi Jinping« since it has successfully maintained deliveries of rare‑earth magnet alloys during the recent strategically motivated Chinese export restrictions by unlocking stockpiles and reviving production lines. Strategically, LCM is unique outside of China for its midstream metal‑making capabilities. The vital elements Nd and NdPr master alloy are processed by the method of molten‑salt electrolysis and SmCo is produced through co‑reduction, processes by which the Chinese ordinarily by virtue of their unique production capability position, can leverage chokepoints which will ultimately determine whether Western primes can keep building high‑temperature magnets for aviation and defence. LCM is expanding electrolytic capacity and has installed furnaces to produce heavy rare earth metals (Dy, Tb) that will harden magnets against demagnetisation at high temperature which is directly relevant to fast‑jet and naval use. In late 2025, USA Rare Earth, an American company that mines and processes rare earth materials, bought LCM. The company highlighted LCM’ ability to make metals and strip-cast alloys as a key part of creating a full „mine-to-magnet” supply chain for allied customers, including U.S. magnet makers.

Ionic Technologies: Recycling and sovereign buffers

This Belfast based company received an £11 million investment from the UK’sAdvanced Propulsion Centre (CirculaREEconom) and their demonstration plant is designed to recover high‑purity rare‑earth oxides from end‑of‑life magnets. The goal of their operation is to secure a sovereign supply for UK metal‑making and magnets, proving a recycling model that will reduce import dependence and strengthen resilience during any possible export disruptions. Ionic leads a consortium with Ford, Bentley, Wrightbus, Less Common Metals and the British Geological Survey, aligning automotive electrification with defence‑grade material assurance.

Metalysis (South Yorkshire): Strategic grams for aerospace & semiconductors

This company has begun commercial production of high‑purity aluminium–scandium (Al–Sc) alloy powders using its FFC Cambridge electrolysis process. Scandium is a performance multiplier in small quantities for application in strengthening lightweight structures (airframes, missiles) and enabling AlScN films for RF filters in secure communications and sensing. These are precisely the high‑reliability grams that matter so much in defence supply chains. While per‑unit output is somewhat modest, the midstream capability is strategically decisive because defence requirements prize purity and reliability over tonnage.

Allied Research & Development in Britain: Safran's UK hub for magnet alternatives

Safran the French Aerospace company and the world’s leading jet engine maker, has selected its Buckinghamshire site to lead European research on alternatives to constrained rare earths (e.g. samarium) and to explore rare‑earth‑lean magnet concepts for future hybrid‑electric propulsion which explicitly provide an answer to the weaponisation of supply chains which could potentially happen. Hosting this work in the UK has the additional benefit of embedding allied engine‑maker know‑how within Britain’s materials ecosystem, with potential dual‑use benefits for both civil and defence propulsion.

What are the risks and challenges?

Time Factor Risk: These UK projects will only succeed if construction and testing stay on schedule according to planned timelines. Success will be measured by whether companies like LCM and Metalysis hit their commissioning dates and deliver consistent, high-quality product output.

Supply Chain Risk: Supply of heavy rare earths such as dysprosium and terbium is very limited worldwide. Strategic partnerships like Rainbow Rare Earths supplying oxides to LCM (2023 Agreement), most certainly help but they are dependent on stable international geopolitical relations and long-term contracts. Any even slight disruption to either would have an immediate impact across the supply chain which being extremely restricted will result in critical shortages.

Flooding of Global REM Market: Another point to consider could be that China could equally suddenly flood the REM market with cheap elements to undermine resilience efforts undertaken by the West and then reinstitute restrictions to continue exerting near full control.

Licensing and Export Risk: Even with newly developed UK capacity, some steps of the whole REM acquisition process, still cross borders and changes in export controls or standards could choke magnet supply. Close coordination with allies will therefore be essential to prevent delays that could affect aviation and missile programmes.

Recommendations for mitigation of risk factors

To manage these risks, several strategic actions are recommended:

- Securing long-term purchase agreements with UK producers for defence-grade batches, to include options for stock surge supply and high-temperature magnet compositions.

- Integration of recycled feedstock from Ionic Technologies Belfast plant into NATO supply chain specifications to reduce reliance on non-allied imports.

- Supporting joint research between UK and foreign allied institutions to develop magnet chemistries that use fewer rare earths but still meet performance needs for air and missile systems.

- Harmonising standards and certification for defence magnets across NATO to make cross-border sourcing and maintenance easier while enforcing provenance and environmental compliance.

- Building up contingency stockpiles of heavy rare earths and qualified alloys in NATO depots to protect critical programmes from export shocks.

This whole question is not merely industrial, but it is fundamentally geopolitical. China controls over 90% of global rare earth refining and alloy production, giving Beijing significant leverage over advanced technology supply chains. By developing, maintaining production and expanding capacity in the UK, Western nations will have greater ability to counteract Chinese chokepoints and economic coercion by avoiding relying on non-allied and rival export regimes. This will be existentially vital should military operations ever occur, and production needs to ramp up quickly.

The question is now as to whether the wider allied political decision-making community will grasp the full seriousness of what the possible implications of a China chokehold would be? Now more than ever a whole-of-alliance effort needs to be made to ensure Rare Earth Metals critical sovereignty because if not then the consequences for the future could be to allow an adversary to quite literally „call the shots”.

Sources (selected)

- Daily Telegraph: LCM profile (24 Dec 2025);

- Daily Telegraph: Safran in Buckinghamshire (3 Dec 2025);

- MMTA: 'Less Common Metals — building a sustainable REE supply chain' (18 Apr 2024);

- UKCMIC/BGS: 'The potential for rare earth elements in the UK' (2024);

- Mining.com.au: UK backs Ionic (14 Jul 2025);

- DiscoveryAlert: UK supports rare earth supply chains (14 Jul 2025);

- Rare Earth Exchanges: Metalysis Al–Sc analysis (22 Dec 2025);

- USA Rare Earth: LCM acquisition closed (18 Nov 2025);

- Adam Smith Institute: 'The Clock Is Ticking on Britain's Rare Earth Dependence'.