- WIADOMOŚCI

New Round for the Rak Mortar as the Key to Effective Training

Can training on the M120K Rak self-propelled mortars be made cheaper and simpler? The Military Institute of Armament Technology (WITU) proposed a new training solution during the International Artillery Conference in Toruń.

Photo. Adam Świerkowski/Defence24

The M120K Rak wheeled self-propelled mortars are among the most advanced fire support systems used by the Polish Army. All 123 units ordered by the Ministry of Defence were meant to be delivered. However, due to a number of these vehicles (approximately eight) being transferred to Ukraine, fewer units remain in service than initially planned. Rak mortars are valued by artillery operators from both Poland and Ukraine. Soldiers praise their high accuracy and mobility, which allows for rapid repositioning on the battlefield.

Every weapon system requires a well-trained crew to fully realize its battlefield potential. Training crews for Polish mortars has been challenging due to the lack of training or practice-specific ammunition for the Rak. Currently, training is conducted mainly using gap-filler, live munitions, such as the OF-834BM, a version of the OF-834B adapted for use with the Rak. Limited quantities of training variants and the high cost of the Rak-specific RAK-HE-1 ammunition further complicate training. The RAK-HE-1 is significantly more expensive, with costs estimated in 2022 at approximately PLN 11,130 per unit (as per Jerzy Reszczyński’s analysis), compared to around PLN 6,230 for the OF-834BM. A more affordable and realistic training solution is needed.

WITU presented a potential solution during his talk, “Training Ammunition for the M120K Rak with Reduced Range,” at the International Artillery Conference in Toruń. This new training ammunition aims to address multiple issues, starting with significantly reduced unit costs. The simplified design and lack of explosive material in the warhead mean that less combat ammunition is consumed, enabling the military to preserve greater stockpiles for wartime scenarios.

The reduced range of the ammunition allows training to be conducted in locations previously unsuitable for such exercises. This eliminates the need to travel to dedicated artillery ranges, saving time and reducing equipment wear. The maximum range for the training rounds is limited to approximately 250 meters (or less) while maintaining recoil characteristics and other essential features, such as dimensions and weight, similar to actual combat rounds. This allows the artillery units to free some of the training ranges for different purposes, and, overall, make the whole training process regarding the Rak mortar far more flexible.

These properties have been achieved thanks to the very innovative design of the projectile. The ammunition consists of two parts with different muzzle velocities. The first part, the projectile assembly, has greater mass and velocity and is responsible for generating the required recoil impulse; it disintegrates after leaving the barrel. The second component has a lower muzzle velocity and range. As a result, it is possible to fire training ammunition on significantly shorter firing ranges. The range of the training ammunition can be adjusted depending on the propellant charge, tailored to specific needs, similar to firing live grenades.

Interestingly, WITU mentioned the concept of training projectiles that could also simulate munitions’ factory defects. According to the presentation, the risk of quality control issues in combat munitions produced during wartime increases significantly. Such training aids would be marked appropriately to indicate a defect that soldiers should detect, identify, and report to their superiors. If overlooked, the projectile would emit paint upon firing, indicating an undetected defect. This solution would further enhance the realism of the training process, requiring full concentration from mortar operators. As evidenced by the war in Ukraine, many soldiers have been injured due to defective mortar ammunition, and unfortunately, some have paid the ultimate price.

The introduction of the RAK-PRAC-1 grenade into service would not only significantly reduce the training costs for M120K Rak mortar crews but also increase the flexibility and realism of the training process, especially if ammunition simulating factory defects were acquired. Over 100 units of the Rak system have been procured so far. In the near future, this number may significantly increase due to the need for tracked versions to support armored and mechanized units. In this way, WITU (Military Institute of Armament Technology) could once again contribute to the rationalization of defence expenditures, as discussed at the International Armament Congress in late October.

Photo. Huta Stalowa Wola

The concept is very intriguing but requires interest from the military for further development. As Dr. Meda rightly pointed out, projects like this need adequate support because conducting work without the interest of decision-makers is futile. A timeline for the development of this training aid was also presented. The time required to refine, test, and implement the mortar bomb is relatively short (about 18 months), and the costs appear symbolic compared to many recent armament purchases and the long-term savings from replacing live ammunition with training versions.

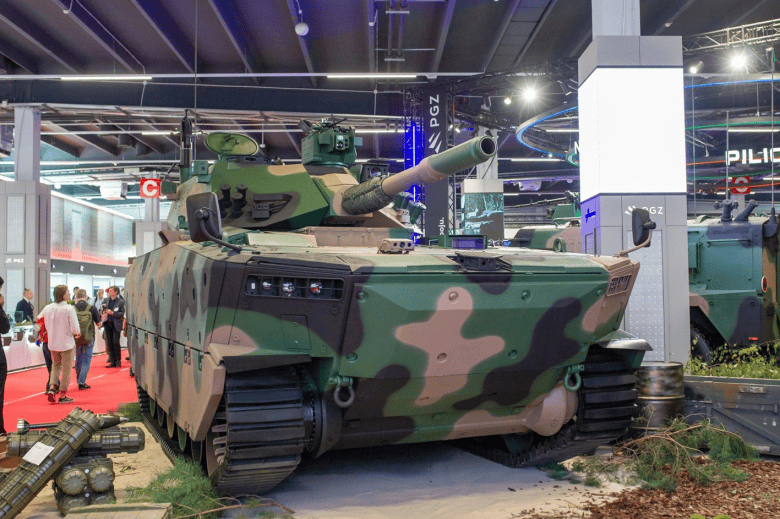

The M120K Rak is a self-propelled 120mm mortar-howitzer. Its manned turret system is mounted on the chassis of the Rosomak APC. The turret body is made of rolled steel plates. Without additional armor, the module provides ballistic protection at Level 1 according to the STANAG 4569 standard. The mortar is breech-loaded. It has been equipped with a mechanized ammunition supply system (autoloader unit). The smoothbore barrel is 25 calibers long. Depending on the ammunition, the range is between 8 and 12 km (work is currently underway on grenades with a range of 14 km). The rate of fire is 6–8 rounds per minute. The ammunition available is 46 rounds, with 20 stored in the autoloader. For self-defence, the platform is equipped with a UKM-2000 general purpose 7.62mm machine gun.

Photo. 15th / 16th Mechanized Division / X

The vehicle is equipped with a modern Topaz fire control system and an observation and aiming device with a laser rangefinder. Thanks to the latter, the Rak can perform direct, flat-trajectory fire (hence its classification as a gun mortar rather than a traditional mortar). The turret is electrically powered, but in the event of a failure, manual rotation of the armament module is possible. The hull armor protects the crew from 14.5 mm caliber ammunition from the front and 7.62 mm caliber rounds from the sides and rear. The Rak is powered by a 490 HP Scania engine, enabling the 24.5-ton vehicle to reach speeds of up to 80 km/h. Currently, Raks are in service with the armed forces of Poland and Ukraine.